Fertigung Ihrer Individuellen Optischen Komponenten

Was auch immer Sie für eine optische Komponente benötigen, Sinoptix bietet die beste Lösung für die Herstellung. Von sehr komplexen, einteiligen optischen Komponenten für die Forschung, bis hin zu hohen Stückzahlen mit einfachen Qualitätsanforderungen für Beleuchtungsoptiken, haben wir die passende Fertigungsoption für Ihr Projekt.

Präzisionsoptik – Maßgefertigt und Preiswert

Sinoptix ist auf Präzisionsoptik spezialisiert und beliefert seit mehr als 14 Jahren Kunden in der ganzen Welt. Unser Team hilft Ihnen bei der Beschaffung von Komponenten, die Ihre Spezifikationen erfüllen: hohe Polieranforderungen, spezifische Rohmaterialien, komplexe Formen und besondere Beschichtungen.

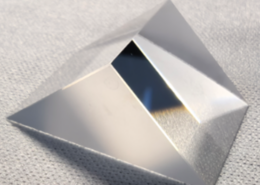

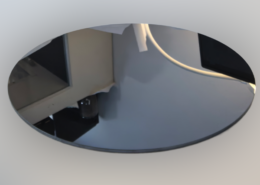

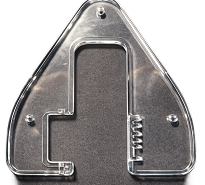

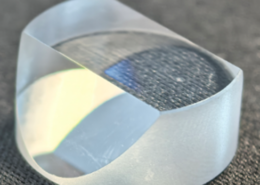

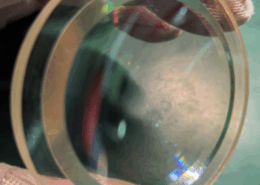

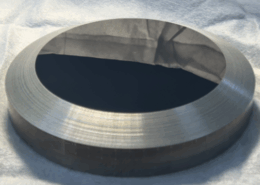

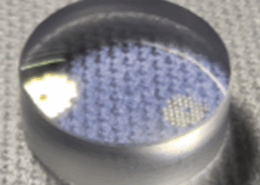

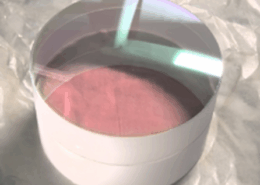

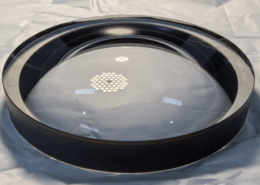

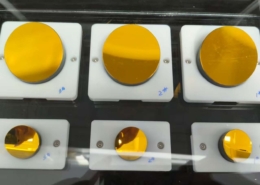

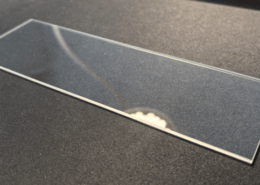

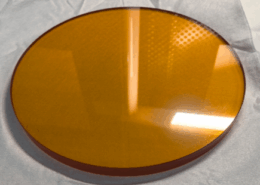

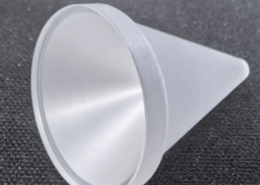

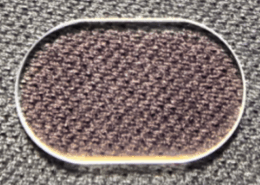

Realisierte optische Komponenten

Der Showroom zeigt verschiedene von Sinoptix durchgeführte Projekte, individuelle Kundenanfertigungen, angewandte Glasbeschichtungen und Materialien. Er bietet einige Beispiele und visuelle Erläuterung für Optik- und Glasfertigungen, deren Umsetzung wir für unsere Kunden anbieten.

Wenn Sie wissen möchten, ob wir Ihre Anforderungen erfüllen und Ihre Projekte realisieren können, setzen Sie sich gerne über das Online-Formular mit uns in Verbindung.

Bitte beachten Sie, dass eine große Anzahl von Projekten aufgrund von NDA und IP-Schutz nicht im Showroom ausgestellt ist.

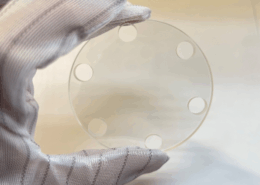

Was ist H-K9L?

H-K9L wird als Äquivalent zu ähnlichen Materialien der großen Marken verwendet und ist eine billigere Alternative mit guten optischen Eigenschaften. H-K9L besteht aus grundlegenden Materialien, die in den meisten optischen Komponenten zu finden sind. Im Bereich optischer Komponenten stellt es eine wettbewerbsfähige Alternative für BK7 dar.

H-K9L ist ein hochwertiges optisches Glas, das immer dann eingesetzt wird, wenn die zusätzlichen Vorteile von Quarzglas (z. B. für hohe Transmissionsleistungen im UV-C-Lichtbereich und tiefem IR-Licht) nicht erforderlich sind. Dieses Material schneidet in allen chemischen Tests gut ab, und es ist keine besondere Handhabung erforderlich. Das Material ist außerdem relativ hart und weist einen äußerst geringen Gehalt an Blasen und Einschlüssen auf. Außerdem bietet es eine ausgezeichnete Durchlässigkeit im gesamten sichtbaren und nahen infraroten Spektrum und bis zu 350 nm im ultravioletten Bereich bei geringer Absorption.

Eine ausführliche Erklärung finden Sie unter H-K9L Erklärt.

Spezielle Eigenschaften von H-K9L

| Hohe Optische Qualität |

| Hergestellt aus den reinsten Rohstoffen |

| Farblose Erscheinung und hohe Transparenz |

| Nahezu frei von Blasen |

| Nahezu frei von Einschlüssen |

| Hervorragende Alternative zu Bk7 |