Optical window : a complete guide

Before the discovery of glass and even until the development of its mass production with the invention of float glass, windows where almost non existant. This changed a lot in the last 3 centuries, and now windows are everywhere from our homes to our cars and mobile phones. Below we will focus more precisely on windows used in Photonics : the optical windows.

Round optical windows

What is an optical window ?

An optical window if an optical component made of transparent material in a certain wavelength range that is usually used for protection of equipment while having little effect on the beam signal.

In a nutshell they are used to avoid external elements (water, air, objects..) to enter the equipment while keeping the optical parameters of a system.

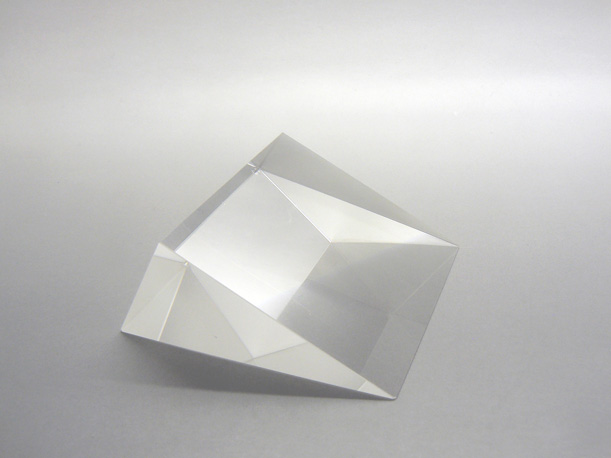

Types of optical windows and applications

Optical windows can be of many different types, round, rectangular, oval or free form shapes. Note that round optics are usually easier to manufacture and to reach high optical specifications, due to their rotational symmetry.

Usually windows width are bigger than their thickness but very thick windows may be used for high pressure applications.

Outside of their shape optical windows can be characterized by their material and their spectrum of application (UV, visible, IR).

Optical windows may also be used as a substrate for further processing. Optical coatings can make them filters or mirrors and metallic coating to offer electromagnetic shielding properties. Finally marking can be added on surface to make optical masks.

Technical details

Which optical materials ?

All optical materials can be used for optical manufacturing, below you’ll find the most common ones :

- B270

- N-BK7(SCHOTT) / HK9L (CDGM)

- Borofloat

- IR materials (Ge, Si, ZnSe, BaF2, CaF2..)

- Sapphire

- Zerodur

- Soda-lime / Float

- PMMA / PC

Usually the harder the material the longer will be the processing time and the higher the price.

What are the typical specifications of an optical window ?

Below table shows some typical specifications that can be reached when manufacturing optical windows:

| SPECIFICATION | USUAL | SPECIFIC |

|---|---|---|

| SIZE | Diameter up to 500mm | D from 0.5mm up to 1.5m |

| TRANSMISSION | Visible range | UV to far infrared |

| SCRATCH & DIG | 20-10 | 10 -5 |

| SURFACE IRREGULARITY | λ/10 | λ/20; λ/100 may be achieved with IBF (Ion Beam Figuring) |

| SURFACE Roughness | 5 to 15 Å RMS | Down to 1 Å RMS (superpolishing) |

| DIMENSIONAL TOLERANCE | +/- 0,1mm | +/- 0,05mm |

| Thickness TOLERANCE | +/- 0,05mm | +/- 0,01mm |

| PARALLELISM | ≤ 10 arcsec | ≤ 1 arcsec |

| CLEAR APPERTURE | 85-90% | 95% |

| DAMAGE THRESHOLD | 5J/cm2 | 20J/cm2 |

| COATING | AR | Custom filtering, mirror, masks, ITO coatings |

Optical window manufacturing process explained.

The key quality point for an optical windows are the material and the polishing quality. Below is the most commun manufacturing steps followed by factories:

- Raw material cutting.

Glass cutting device

- Lapping/ Grinding and Polishing. There are two main equipment to process the laping and polishing :

-

- Pitch polishing machine. Made of a support in metal or granite and moving polishing pitches.

- Double-Sided Lapping & Polishing machine. Made of a upper and lower turning lapping plates and parts are hold in geared carriers with thickness a little lower that the window.

Both are working with polishing pads and polishing slurry which includes abrasive particules, which evolve along the process from gross to fine. Polishing is the longer processing step for windows taking from some hours to half a day per batch.

Pitch polishing equipment

-

- Chamfering is used to break the sharp angles of the windows and so to protect people having to manipulate then, and also reduce the risk of edge breaks on the windows. This process is also called beveling, but can be replaced by rounding of the window edge.

- Strengthening or annealing, are heat treatments that release the stress inside the raw material after manufacturing and therefore minimise the risk of breaking the window by either mechanical or thermal shock.

- Cleaning the parts in ultrasound bath.

Ultrasound cleaning of optics

- Coating, is done according to coating specifications.

Optical coating clean room

Where to buy an optical window ?

Optical windows can be found in optical distributors of flat optics manufacturer. According to the complexity of your specification and material you may need to look for specialist (UV, IR, VISIBLE, SAPPHIRE).

Information to provide to have a quick and accurate quote :

- Material

- Drawing or dimensions (the higher the width/thickness ratio the higher the price)

- Quantities. For polishing flat optics 3 parts are usual manufacturing MOQ and 5 parts or multiple of 5 optimum quantities.

- Optical specifications : surface aspect, parallelism and optionally transmitted wavefront.

- Coating request if any

If you are looking for a supply solution or need support for your request for quotation, don’t hesitate to click on below link to contact SINOPTIX for your optical window project.