Our Quartz / Fused silica parts solutions

When you are looking for heat and chemically resistant material you naturally think about synthetic quartz or fused silica. Quartz is relatively easy to work with, it can be blowned in tubes, machined to complex forms, mechanically or fire polished, and being transparent or opaque.

As you can see below SINOPTIX have solutions for quartz tubes, quartz plates and windows, and custom machined quartz parts.

Quartz / fused silica characteristics

Quartz (SiO2) is a natural material which is possible to recreate industrially.

Characteristics chart of Quartz / Fused silica : JGS1/ JGS2/ JGS3

| Specific characteristic | Comments |

| Chemical stability | Very good (except with Fluorhydric acid) |

| Electric insulation | Very good |

| Fusion temperature | Fusion point at 1650°C |

| Thermal resistance | Very good (0.5×10-6 /K) |

| Optical characteristics for natural quartz | transmission from visible to 4µm. Quartz can also be opaque |

| Optical characteristics for fused silica | Good transmission possible from UV (170nm) to NIR (3 µm) |

| Machining | Relatively good compared to other glass products. Quartz can be molded, drilled, grinded, turned, polished, milled, welded or extruded (fiber optics) |

Quartz tubes, quartz crucibles and quartz discs applications

Following above characteristics, Quartz have numerous industrial applications :

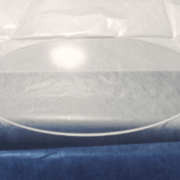

– Quartz windows are used to look into processing equipment, providing good protection against temperature and chemicals while keeping a good optical transparency.

– Quartz crucible, transparent or opaque are used as a recipient for processing materials at high temperature.

– Quartz tubing are popular choice for Laboratory equipment and chemical processing plants.

Machining quartz

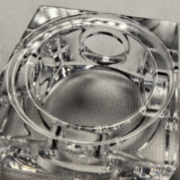

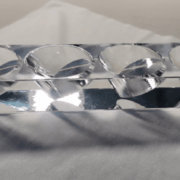

Quartz is a material that can be machined, blew or welded. It is usually easier to process than soda-lime glass or even borosilicate. Custom shapes can be made according to customer requirements, from simple quartz plates to more complicated welded assemblies. Finishing is usually done by grinding, fire polishing or even mechanical polishing.

Quartz utilization in optics

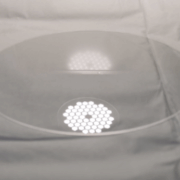

Quartz have interesting optical properties with a wide spectrum of transmission from UV to mid-IR while being fully transparent in the visible range. Optical fused silica material is common and its price is very competitive compare to many other optical materials.

Quartz (SiO2) is a natural material which is possible to recreate industrially.

Quartz in China

On top of the imported quartz brands (Corning 7980, Nikon NIFS, Heraeus Suprasil), there are 4 principal quartz quality :

– Quartz for industrial non optical usage with no specific denomination, usually produced locally.

– Three Fused Silica grades JGS1 / JGS2 / JGS3 for optical applications :

Comparison chart of Chinese fused silica

| Parameters / Values | |||

| Transmission (more than 80%) | 170nm to 2.1 µm | 260nm to 2.5 µm | 190nm to 3.2 µm |

| OH- concentration | 1.2% | 150 ppm | 5ppm |

| Remarks | Less material impurities, higher price | Few material impurities, competitive pricing | Lot of material impurities, usage not recommended |

| Density | |||

| ABBE constant (V) | |||

| Refractive index (nd) @588nm @588nm | |||

| Material Hardness | |||

| Poisson Constant | |||

In China there is numerous Quartz suppliers with unequal level of quality of raw material and processing. Stability in time and repeatability are problematic due to high turnover of qualified professionals. It is therefore necessary to have a close local follow-up of suppliers coupled with a panel of potential replacement suppliers to avoid procurement issues. Sinoptix is the ideal partner to guaranty quality stability of your quartz components from China.

How much cost quartz parts ?

The most impacting points for the valuation of a quartz part are the dimension and tolerancing of the parts. Quantities may also have an important impact on optical fused silica components as polishing can be done in series, and eventual coating in batches.

Tell us the specifics of your project, we will come back to you very quickly with a clear and competitive price offer.