Optical sapphire glass : a complete guide

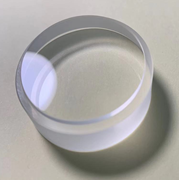

Optical sapphire, can be also called synthetic sapphire, is mainly used for its mechanical, thermal and optical properties in opposition of natural sapphire that is used as a gemstone in jewelry for its cosmetic properties.

Sapphire usage in optics is not new but democratizes as the production costs of sapphire crystal has been reduced a lot, more and more precision optics manufacturers add them to their catalogues.

Optical sapphire properties

There are different methods of producing sapphire crystals, most common ones are : ISM (polycrystalline), KY HEM and EFG CZ (Monocrystalline), characteristics may varies from one raw material supplier to an other, but in order to better understand the material, please find below some general information of synthetic sapphire properties.

Summary table of the sapphire specifications :

| Specification | Data |

|---|---|

| Chemical Formula | Al2O3 |

| Aspect | Colorless transparent |

| Melting point | 2030°C (3686 °F) |

| Maximum operating temperature | 1900°C |

| Thermal conductivity | 41.9 (W/m°K) |

| Thermal expansion 20-1000°C | Parallel to axis C: 9.03×10-6 °C Perpendicular to axis C: 8.31×10-6 °C 60° to axis C: 8.4×10-6 °C |

| Hardness | 1370 (Knoop Number) – Mohs 9 |

| Tensile Strength | 400 MPa (8500 PSI) |

| Flexural Strength | 1900 MPa (13500 PSI) |

| Specific Gravity | 3.95 – 4.03 |

| Poisson’s ratio | 0.25-0.30 |

| Optical transmission | 200 to 5500 nm |

| Refractive index | 1.7122 |

| Chemical resistance | Inert to acids and alkalis and insoluble in water |

Optical transmission curve of sapphire

As can be seen below sapphire have a high transmission from the UV (200nm) to the IR (MID-IR). Transmission may be increased with Anti reflect coating.

Optical sapphire transmission curve

Sapphire crystal structure is not isotropic, orientation of the crystal structure of the material will have an impact on its optical properties.

Sapphire optics usage

Sapphire is much appreciated for its hardness (Mohs 9 – Knoop 1370) which is second only to diamond (Mohs 10 – Knoop up to 10000). This makes the sapphire material virtually scratch resistant and therefore is widely used for watch windows and used for many security applications by protecting cameras or sensors against external agressions. Sapphire is also widely used for mobile phone screens, but is being replaced by other types of specific glass like Corning Gorilla Glass.

Sapphire can also be used to make lenses, aspheres, prisms or wafers, its high resistance to chemicals and temperature is interesting in some extremes applications.

Furthermore, many defense rockets also use sapphire domes as rocket head where optical devices can be well protected against very harsh environment while keeping good optical transparency.

Due to its high transmission in UV, optical sapphire is often used as an alternative to fused silica, when external environment may be harsh.

Finally sapphire is also used as substrat for electro-optics components, production of sapphire wafers and sapphire windows with metallization are developing frantically.

How much does optics in sapphire cost ?

Optical sapphire production costs have been reduced significantly in the last 10 years due the multiplication of synthetic growing facilites around the world. Nevertheless as synthetic sapphire is very hard, its machining and polishing requires special tooling and long processing time which make sapphire optics more expensive than most optical glass optics.

In a rule of thumb, a step in increase of optical requirement may lead to an exponential price increase, it is important not to over-specify sapphire optics.

Don’t hesitate to contact SINOPTIX for getting advises and a quick quote on your project.