Optical mirror : a complete guide

“Magic mirror on the wall – who is the fairest one of all?”.

While this guide won’t provide the answer to the Queen’s question in Disney’s classic Snow White and the Seven Dwarfs, it will give you a glimpse of the optical mirrors available on the market and help you select the best one to suit your needs.

Optical mirrors

Optical mirror definition

An optical mirror is a precision optics component made of a optical polished substrate material and a high reflection coating. It can be of various shape and dimensions from less than a millimeter to several meters.

Optical mirrors are found in all the Photonics applications : in astronomy inside every telescope, in lasers by design, in vision equipment, and most of the optical assemblies systems. While their usage is quite simple : reflect the light, their range of application is wide, from UV to IR it can be used to transmit light with a change of direction, to focus light (for example in a Cassegrain telescope) or pumping light in a laser.

Types of optical mirrors

Shapes

Under the name “mirror” are many different types of precision optics that may be sorted as one of below type :

- Flat mirror, it is the simplest form similar to bathroon mirrors with higher precision.

- Spherical mirror, relates to mirrors with a radius of curvature either concave or convex.

- Aspherical mirror, more complex shape mirrors designed to attenuate optical aberration of reflected beam. For example : off-axis parabolic mirrors which are used to collimate a bean à 90° angle.

- Elliptical mirrors, are usually used at a 45° angle where they provide optimum circular clear aperture.

- Concave mirrors, the concave shape increase the reflection that can go more than 99% with an angle of incidence (AOI) of 0°.

- Freeform mirrors

- Prism mirrors, can be used either with outside reflection or inside reflection.

Substrate material

Mirrors substrate material are usually selected for their good shape resistance to temperatures changes, easiness of coating to bound with it and easiness of polishing to guaranty a good polishing shape. For some high power laser applications, substrate can also be the in LIDT constraint and therefore be selected carefully.

Below table shows most common substrate material for mirror blanks :

| Substrate material | Remarks |

|---|---|

| Float | Very cheap material that comes with acceptable polishing and flatness level for low requirement applications. |

| Fused silica | Resistant material with good optical machining properties, very commonly used. |

| N-BK7 / H-K9L | Most common optical glass, can be used for high requirement surface aspects. |

| Zerodur | Material almost non affected by low temperature, used mainly for space applications. |

| Metals | Polished aluminium or brass can be used for some high power laser applications, they are also easier to machined than glass type material and mechanicaly stronger. |

| Plastics | Plastic substrates are used in optical applications, but the difficulty to keep a good surface quality and the easy wearing of the parts due to outside environment limit its usage, while this remain the cheapest substrate material. |

Remark : for some applications where mirrors maybe of important dimensions and the part weight is an important constraint like in space industry for example, a lightening of the part can be done with a structuring of the back of the substrate.

Mirror coating

The most important part of an optical mirror is its high reflection coating, it is that coating that will be at the interface of incident beam and reflect it to an orthogonal direction.

Optical coating workshop

Broadband dielectric coatings

With the improvement of vacuum deposition equipment in the last 30 years, layer of dielectric material can be deposit of substrates with a nanometric precision.

The material and the thickness used for each layer enable the trimming of a broadband of wavelengths where the incident beam will be reflected.

It has to be noted that the reflection of such mirror degrades as the AOI increases.

Metal-coated mirrors

| Coating metal | RefLection | Indicative damage threshold | Remarks |

|---|---|---|---|

| Protected* silver | Ravg>97.5% on the visible + NIR, Ravg>96% on MIR+FIR | 3J/cm2 | Very good reflection in the visible |

| Protected* Aluminium | Ravg>90% on the visible + NIR, Ravg>95% on MIR+FIR | 0,3J/cm2 | A MgF2 layer can be added to improve reflection in the UV (250 to 400nm) |

| Enhanced Aluminium | Ravg>95% on the visible + NIR, Ravg>85-90% on MIR+FIR | Low | Sensible to exposure to external environment, handling and cleaning |

| Protected* Gold | Ravg>96% on the IR | 2J/cm2 | Without surprise the most expensive of the metal coatings. |

*Metal coatings are protected with SiO2 layers in order to avoid corrosion.

**An additional Chromium layer is usually added between the substrate and the metal to improve adhesion.

Laser mirrors

The critical specification for optical mirrors to be used in laser applications is their LIDT (Laser Induced Damage Threshold, or in short Damage Threshold).

This specification often measure in J/cm2 defines the energy that can be accepted by a surface area. (for reminder Watts are defining a power so values in Watts should be integrated in the time to be translated to energy).

LIDT should be defined with detail of the type of reference laser : CW or pulse laser, pulse duration, frequency and power.

Usually the coating is the contraint before the substrate, but for high power laser substrate can be wear by laser usage too. The lower the polishing and the higher of impurities in the material will bring to lower LIDT of the substrates.

Superpolished mirrors

Superpolised mirrors refers to mirrors with very high surface quality (superpolishing) with RMS of less than one Angström and low loss IBS dielectric coatings. They are often used for laser applications.

Deformable mirrors

Deformable mirrors are active optics elements used in adaptative optics. They are typically made of an optical membrane, actuators and an electronic controller.

Their main usage is compensating aberrations, from example of the atmosphère in astronomy, of the eye in ophthalmology or of the cells water in biomicroscopy.

Main suppliers of deformable mirrors are ALPAO and ISP-System for high power applications.

Hot mirrors and cold mirrors

What are Hot mirrors and cold mirrors ? It is rather intuitive (while sometimes confusing) :

- Hot mirrors are reflecting the IR part of an incident beam and transmit the visible part of it.

- Cold mirrors are transmitting the IR part of an incident beam and reflect the visible part of it.

In a nutshell : Hot mirrors reflect warmth, cold mirrors reflect cold signal.

They are used to separate visible to IR parts of an optical signal.

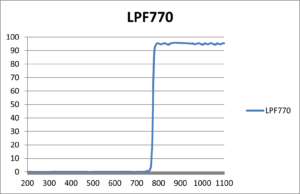

Transmission curve of a cold mirror

Where to buy optical mirrors ?

Like most optical components optical mirrors are bought from precision optics manufacturers & distributors. It is rather common that the substrate and the coating are made in two different site, therefore buying mirror blank and doing the coating in-house or subcontracting it to other supplier is common practice.

Don’t hesitate to contact SINOPTIX for your questions about optical mirrors or to request for a quote.