Borosilicate glass : a complete guide

Often call “Pyrex” by the public, borosilicate or boro as it is often called is a grade of glass that has been widely used since more than 100 years from cookware to optical parts.

In this article you’ll learn everything you need to know about Borosilicate glass.

What is borosilicate glass?

Definition

Borosilicate glass refers to a glass (inert transparent solid) including more than 5% of Boric oxide (B2O3) mixed with SiO2, Al2O3 and Na2O. It has a very clear optical transparency and good mechanical properties. Borosilicate is also often used for its resistance to temperature, temperature shocks and chemical agents.

Resistance to temperature shocks, makes borosilicate the perfect material to be used in making cookware that won’t break when taken out of oven and contact much colder material. Also, the heat and chemical (both alkali and acid) resistance are the reason why borosilicate is a material seen in many laboratory equipment.

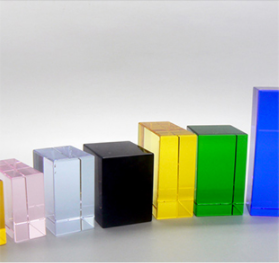

Colored borosilicate

Adding ppm of chemical element can produce very stable colored borosilicate material.

For exemple, Fe element will produce green glass, gold elements will make the glass red, while copper and cobalt will be used for blue colors.

Colored borosilicate blocs

Lampworking

Borosilicate requires higher temperatures to work with, but if preferred by lamp-workers for complex shape parts. Raw material used is in shape of tubes so it can be blown into shapes, colored tubes are also commonly used.

Flat glass

Borofloat is manufactured with the same process as float glass, making cheap very flat glass material plates of different thickness. Therefore borosilicate is a material of choice for window manufacturing.

NB: The maximum thickness available in China is 19mm, it is possible to make thicker plates by gluing several plates but the optical quality is degraded (presence of water marks visible to the naked eye). In imported borosilicate, it is possible to go up to thicknesses of 25mm.

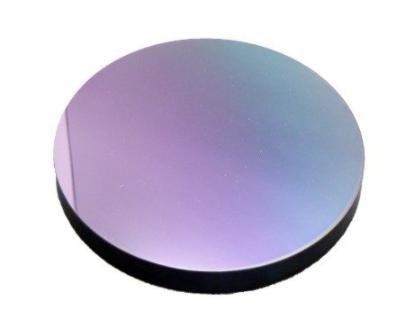

Optical glass

One of the most common optical glass, Schott N-BK7 is a crown borosilicate, so are its equivalent H-K9L from CDGM and B270 glass.

Borosilicate lens

What is the difference between borosilicate and normal glass ?

The main difference, as its name put it is the presence of Boron in the material, which enable a resistance to higher temperatures than soda-lime glass but also borosilicate need to be produced at higher temperatures making it more expensive to produce.

Borosilicate glass has a 3 times higher thermal expansion coefficient making it much better at handling thermal shocks.

Both materials can be produced in flat plates with the float process, float Soda-lime is usually referred as “Float” and borosilicate differentiated as “Borofloat”.

Whereas soda-lime glass has a greenish color borosilicate is very clear, it even can be used for high quality optics while soda-lime glass is seldom used only for low quality optics.

Borosilicate properties

Borosilicate are name after their thermal expansion coefficient, most common ones being Boro 3.3 and Boro 5.0. Below table cover most of the common specifications of borosilicate :

| Specification | Value |

|---|---|

| Density | 2.2 g/cm3 |

| Knoop hardness | 480 |

| Young’s Modulus | 64 kN/mm2 |

| Poisson ratio | 0.2 |

| Thermal expansion coef. | 3.3 to 5.1 x10^6 K^-1 |

| Thermal conductivity | 1.2 Wx(mxK)^-1 |

| Maximum operating temperature | 500°C |

| Resistance to thermal shock | up to 180°C |

| Softening point | 820°C |

| Refraction index | 1.5 |

| Abbe constant | 65 |

| Transmission | >90% from 320 to 2800nm |

Where to buy borosilicate parts ?

It depends of your application. For tubes and plates raw materials manufacturers can be contacted, for cookware press factories and lampworkers can be contacted while for Crown Borosilicate optics precision optics supplier should be contacted.