Waveplate for optics : a complete guide

Understanding light, how it is made of photons how it behaves like an electromagnetic wave has been a long and difficult journey. Optical waveplates are one of the tool that came from this research and that enable us to make the most of light signals and so to enhance our comprehension of the world around us. Below you’ll find complete explanation about optical waveplates :

Illustration of waves

What is a waveplate ?

Before giving an answer to that question it is important to understand that light signal, which interact like a wave, can be resolved in to orthogonal polarisations usually called p and s. To simplify with an image in a classic x,y,z orthogonal projection, a light wave going into a z direction will oscillate along the z axis in x and y directions.

Waveplates will modify the relative phase of p & s polarisations. Practically it will delay a polarisation from an other, hence waveplates are also called retarders.

Half waveplates

Half waveplates will delay a polarisation phase of π making it the mirror image of the incident polarisation.

Half waveplate

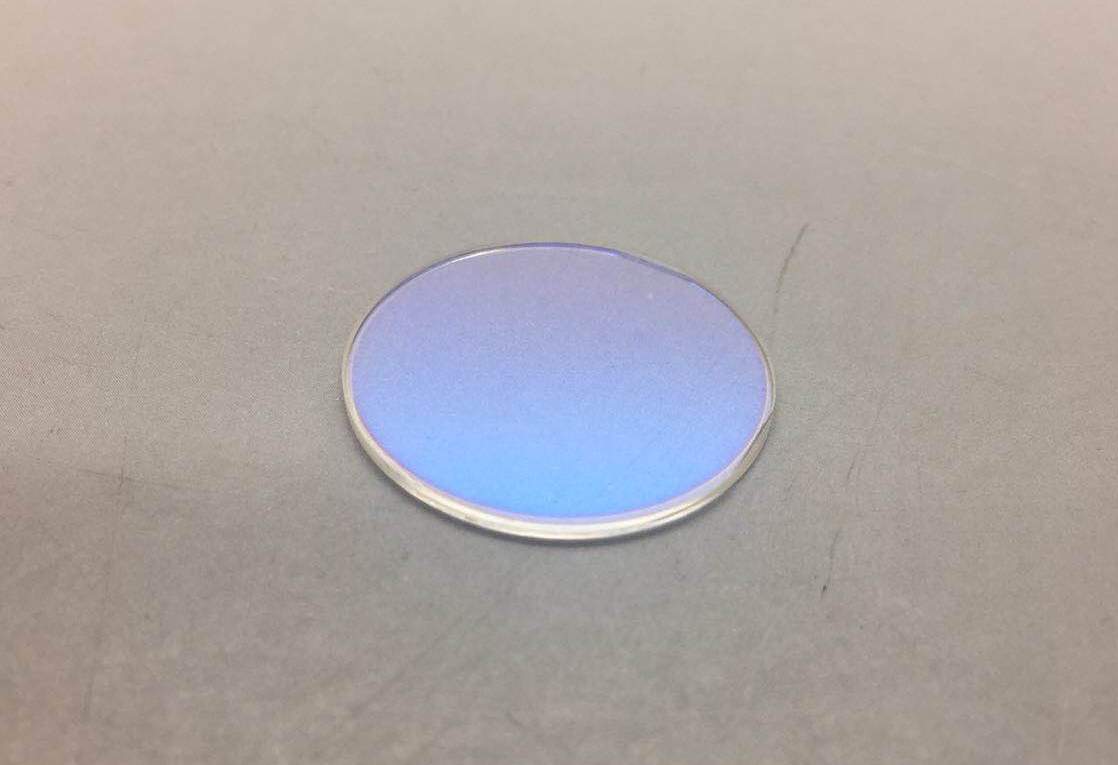

Quarter waveplates

Quarter waveplates will be used to delay polarisation of π/2. Quarter waveplate can change linearly polarized light to circular polarization at its output.

Quarter waveplate

Full waveplates

Full wave plate will retard one of the polarisation to a full cycle.

How are made waveplates ?

Waveplates manufacturing rely on the birefringence of some optical material. Birefringence being the characteristic that bears some materials having different refractive index in different orthogonal directions. We will then speak about a fast axis and a slow axis making the delay between polarisation while the light is going through the waveplate.

Waveplates can be made out of different birefringent materials: mostly crystals or polymers.

We can differentiate :

Multi-order waveplate

The real retardation of one polarization to an other is serval times the wavelength plus the expected nominal retardation. It can be seen as the position a car wheel it would be the same if it turns only 45° or 10 times on itself plus 45°.

Multi-order wavepates are thicker than true zero-orders ones, so more mechanically resistant and with higher LIDT. But they are less precise especially when there are temperature variations as the birefringence of the materials change with the temperature.

Zero-order waveplate

A zero-order waveplate only retard the signal of the nominal value. (whitout extra turn of the wheel in our car wheel example).

They can be manufactured either with very thin material film (usually sandwiched between two optically neutral windows for more mechanical stability), or several multi-orders waveplates positions in different angles in order to eliminate the retardation shifts (extra turns of the wheel).

As the retardation is in the order of the wavelength, for both waveplates types it is important to have a high quality of the optical part with surface quality as high as λ/10.

It is also important to understand that a waveplate is designed at a specific thickness for a defined range of wavelengh at a specific angular position.

Where to buy waveplates ?

Manufacturers of waveplates usually also provide other precision optics components but not all precision optics supplier can provide waveplate. Very precise calculation and positioning along the optical axis of the crystals should be done. It is therefore important to work only with suppliers experiences in waveplates.

Don’t hesitate to contact SINOPTIX for more details: