Micro-optics diamond turning

Micro-optics diamond turning is a manufacturing process used to create precise, small-scale optical components, including lenses, prisms, and mirrors. In this article, we will explore the basics of single point diamond turning, the advantages of the technique, and its applications in the field of optics.

What is Diamond Turning?

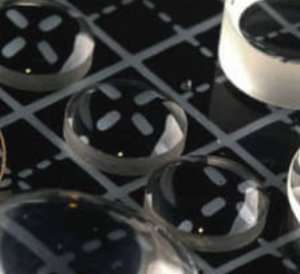

Diamond turning is a machining process that involves the use of a sharp diamond tool to cut and shape materials. It is a highly precise technique that can be used to create complex geometries with high accuracy and surface quality. In micro-optics diamond turning, the diamond tool is used to shape optical components on a small scale, typically with diameters in the range of 1 to 10 millimeters.

The process of diamond turning involves mounting a workpiece onto a lathe and rotating it at high speeds, typically 5000 to 18000 RPM (Rotation Per Minutes). A diamond tool is then brought into contact with the surface of the workpiece, and the two materials rub against each other, removing material from the workpiece and shaping it into the desired geometry. Precitech is one of the leading provider of single point diamond turning machine for micro-optics manufacturing.

Advantages of Diamond Turning

Single point diamond turning has several advantages over other manufacturing processes for micro-optics. Some of the key benefits include:

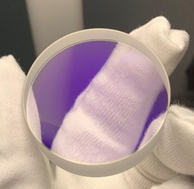

- High precision: Diamond turning is capable of producing parts with very high precision, typically on the order of a few microns or less. This makes it well-suited for creating micro-optics components that require precise geometries and surface finishes. Surface aspects can reach 4 nm RMS, and surface figue 100 nm PV.

- Versatility: Diamond turning can be used to create a wide range of optical components, including lenses, prisms, mirrors, and other specialized components. It is highly recommended for freeform micro-optics. It is also compatible with a wide range of materials, including metals, plastics, and ceramics.

- Cost-effectiveness: Compared to other manufacturing techniques, diamond turning can be a cost-effective option for producing small quantities of high-precision components. This is because the tooling costs for diamond turning are relatively low compared to other processes, such as injection molding or lithography.

Which optical materials can be diamond turned ?

Single point diamond turning can be used with :

- metal material (copper, brass, aluminium).

- optical plastics like PMMA or COP, but not with PC which is to soft.

- IR materials as Germanium (very effective), ZnS, ZnSe, chalcogenide glass and Silicon (with difficulties).

Optical glass (like N-BK7 / H-K9L ..) are not yet workable by this process.

Applications of Diamond Turning

Diamond turning is used in a wide range of applications in the field of optics, including:

- Imaging: Micro-optics components created with diamond turning are used in imaging systems, such as microscopes, endoscopes, cameras, and telescopes. These components help to focus light and reduce optical aberrations, they are mainly used in small devices like mobile phones cameras.

- Telecommunications: Diamond-turned components are used in telecommunications systems, such as fiber-optic networks. These components help connecting optical fibers with optical receivers with high efficiency and low loss.

- Sensors: Micro-optics components can be used in sensors for a wide range of applications, including environmental monitoring, medical diagnostics, and industrial process control.

In a nutshell

Micro-optics diamond turning is a highly precise manufacturing process that is well-suited for creating small-scale optical components with high accuracy and surface quality. The process has several advantages over other manufacturing techniques and is widely used in a range of applications in the field of optics. Whether you are working on a research project, developing a new product, or producing components for industrial applications, micro-optics diamond turning may be a valuable tool in your arsenal.