Laser optics : a complete guide

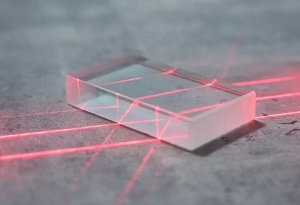

When we speak of lasers, we think of coherent light, a very narrow bandwidth, and power. These characteristics needs to be taken into account when using optics with laser beams. Below you’ll find guidelines for the selection of laser optics.

Laser optics

What are laser optics ?

Laser optics are specific optical elements that are designed to be used for laser applications. Light beam emitted from a laser is usually more intense than random light emission and uni-directional.

In order to focus, transmit, filter or redirect a laser beam, you need specific optics that are designed for the purpose and most of the time to the kind of laser that will be used too. Elements for a CW (Continuous Wave) laser of pulse laser may be different, same a component used for a 266nm laser may not fit for a 1064nm laser.

In a nutshell, laser optics are components designed for a specific usage with a specific laser.

Damage threshold for laser optics

Damage threshold or LIDT (Laser Induced Damage Threshold) is the maximum amount of energy (usually expressed in J/cm2) that can be handled by an optical element without deteriorating.

Whereas LIDT is critical for high power laser application, its definition and measurement are not very straightforward. As laser are usually monochromatic a LIDT should be defined for a specific wavelength, laser optics are designed for an application and will not react in the same way for other applications. Also it should be specified if the laser is CW or Pulsed (with the pulse rate).

How to optimize laser optics LIDT ?

Damage threshold is linked with the amount of energy that is absorbed by an element, a virtual element with 100% transmission would not have LIDT. In order to be the closer to the 100% transmission laser optics have to be manufactured and selected following different elements :

- Raw material : should be with high transmission in the selected wavelength, and with virtually no impurity as impurity will be heated by the laser beam energy and then deteriorate the optics.

- Surface : the better the polishing the higher the transmission through the optics so the lower the absorption. Using super-polished elements is one way to improve LIDT.

- Coating : Anti-reflect coating will improve transmission, in laser optics they are usually sharp focused on a specific wavelength (reflection curve looking like a “V”) in order to achieve the lowest reflection values. IBS coating is to be preferred to evaporation coatings as it enables a higher layer density and therefore low water and impurities absorption.

- Cleanliness : LIDT depends on the surface quality of an optical element, non clean element will deteriorate their damage threshold performances. Manufacturing and handling are often done in cleanrooms for high power elements.

How to measure laser optics LIDT ?

Measuring LIDT is not straightforward, it is a destructive testing and needs expensive Equipment.

The process is to apply a laser beam on the optic to be tested and to visually analyse the eventual damage. Several tests can be conducted on a same optics in order to fine tune the LIDT value.

As explained above a LIDT is linked to a specific kind of laser, so to be able to test a LIDT one should be able to test it with a corresponding laser device, there are rules of thumb to extrapolate LIDT from one laser type to an other but they are not very accurate and cannot used as a basis for an optical design.

As the testing itself is destructive testing and the laser optics are neither very cheap, LIDT is often guarantied by the respect of other specifications (material, type of coating, polishing, cleanliness) .

Which optical materials for laser optics ?

As we have seen it is really important to choose the good optical material with high transmission in the wavelength range of the laser. It is also important to select material with low impurities, some material manufacturers are even referring to high purity optical material as “laser” grade material.

Some example of materials used in laser optics:

- ZnSe for laser in the MidIR (8-12µm)

- CaF2 Nd:YAG lasers (266nm & 4µm), due its low absorption it can stand high LIDT it is therefore often used for Eximer lasers.

- MgF2 : for UV and Eximer lasers.

- For C02 lasers (10,6µm) : Zinc Selenide (ZnSe), Germanium (Ge), Galium Arsenide (GaAs) and Silicon (Si)

- N-BK7/ H-K9L are also good substrate for laser optics providing that they are not used in too high power.

- Fused silica is often used for laser optics due to it’s high purity (more than 99,99%)

Different laser optics components

Different kind of laser optics and their specific usage:

| Element | Usage |

|---|---|

| Lens | focusing of laser beam |

| Aspherical lens | better focusing of laser beam |

| Laser mirrors | Redirection and distribution of laser beam (for example for scanning applications), CO2 laser mirrors. |

| Laser cavity mirrors | Total reflection mirrors & output mirrors |

| Filters | Improve the quality of the beam or reduce beam intensity |

| Laser windows | Protect optical equipment from external elements |

| Waveplate | Differentiate laser beams |

| Beamsplitter | split a beam in two lower intensity beams |