IR optics: BaF2 an alternative to germanium ?

Ge is the most used optical material for thermal optics, can it be replaced by other material ? In this article we will examine Barium Fluoride as a contender of this dominant position.

Difficulties of sourcing germanium optical components

Difficult availability

China is the world’s main producer of germanium, a strategic element used in electronics. Recently, the country has imposed strict control over the use and export of germanium, likely in response to US sanctions on chip technology. Accessing raw germanium is now much more difficult, as exports must undergo a lengthy and uncertain approval process by Chinese customs.

Though germanium is widespread across the globe, it only exists in small concentrations. Refining it into high-purity optical grade material requires complex equipment. Therefore, other countries will face significant challenges in replacing their germanium supply without heavy investments in mining and refining.

Volatile pricing

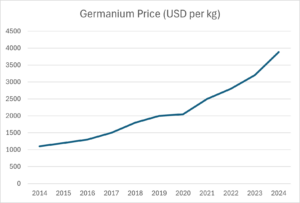

As shown in the chart below (data from tradingeconomics.com), the price of germanium has steadily increased over the past decade, experiencing a 3.53-fold rise. Recent trends indicate not a stabilization but rather an accelerated pace in the cost increase. As of October 2024, the current price is $3,883 per kilogram, making germanium a considerably expensive material.

Can BAF2 be an alternative to germanium?

Barium Fluoride and Germanium share commun good transmission in the IR and particularly the thermal IR spectra, but they have different characteristics, below chart summarize the most relevant ones.

| Barium Fluoride | Germanium | Comments | |

|---|---|---|---|

| Chemical elements | BaF2 | Ge | |

| Transmission range | 0.25-12 µm (T start decreasing @ 9.5µm) | 1.6 – 20 µm | BaF2 is transparent in the visible while Ge is not. Ge goes beyond in far infrareds. |

| Refractive index | 1.47 | 4.0 | Huge difference, meaning that optics would need to be fully redesigned for a switch from Ge to BaF2. |

| Density (g/cm3) | 4.9 | 5.32 | |

| Spectral dispersion | Low | Very low | Both material will show low chromatic aberration, useful to work on large spectrum |

| Hardness GPa | 0.75 (Mohs 3.5) | 6.1 (Mohs 6) | This difference is very significative, BaF2 low hardness make it easy to be damaged. |

| Brittleness | Very brittle | brittle | Both needs careful handling, but BaF2 even more |

| Temperature resistance | Can be used up to 800°C in dry environment (500°C in the presence of moisture) | Optical properties starts to degrade from 100°. | BaF2 is an interesting alternative to Ge for higher temperature usage. |

| Thermal shock resistance | Not good | average | |

| Moisture resistance | Prolonged exposure to moisture will have negative impact on its quality | Will oxide with prolonged exposure to moisture | DLC coating on Germanium will significantly improves its resistance to moisture |

| Dimension availability | Up to D200mm | More difficult to find big diameters | For optics larger than D100mm, germanium will be even more expensive due to the scarcity of the offer. |

An alternative only for limited applications:

While both materials share low spectral dispersion and good transmission on the IR spectra, germanium is much more resistant to environmental elements especially if strengthened with a DLC coating.

In a protected environment like a laboratory, Barium Fluoride shows interesting advantages for optical components : first its pricing (half of germanium at the time of writing) , capabilities to work at higher temperatures and transparency in the visible.