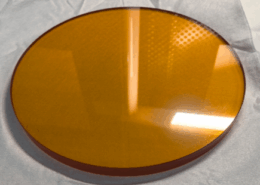

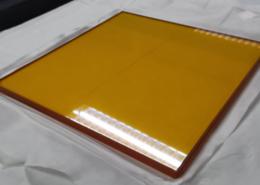

ZnSe optical components

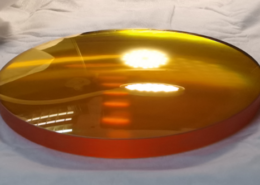

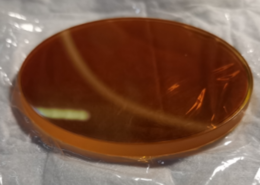

SINOPTIX supplies various optical components made of optical grade Zinc Selenide. ZnSe is a yellowish material, partially transparent in the visible, widely used for CO2 laser optics and IR imaging systems due to its wide transmission spectrum in the infrared.

Zinc Selenide characteristics

Zinc Selenide substrates used by SINOPTIX are manufactured by CVD (Chemical Vacuum Deposition) technology in China.

ZnSe properties chart

| Material denomination | Zinc Selenide |

| Chemical elements | ZnSe |

| Refractive index | 2.50 (2.403 @ 10.6µm) |

| Transmission range | 0.6 µm to 21µm |

| Density | 5.27 g/cm3 |

| Hardness | 120 Knoop |

| Young’s modulus | 71 GPa |

| Thermal expansion | 7*10-6 °K-1 |

| Thermal conductivity | 19 W/(m*°K) |

| Melting point | 1790 °K |

Please visit our complete guide on ZnSe optics to know more.

Zinc Selenide optical components capabilities

Manufacturing capabilities

| Properties | Values |

|---|---|

| Available dimensions | Diam 3 to D300mm |

| Dimensional tolerances | +/-0.01mm |

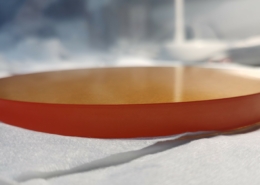

| Thickness | up to 100mm |

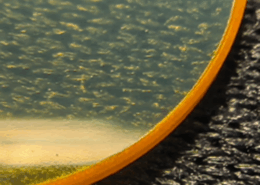

| Surface quality | S&D : 20/10 |

| Flatness | 0.1 lambda |

| Roughness | 2 to 6 nm |

| Parallelism | better than 5″ |

| Thickness tolerance | +/- 0.02mm |

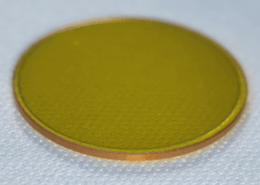

| Coatings | AR 10.6 µm (CO2 laser) or 8-14µm (thermal) |

SINOPTIX ZnSe components references:

Available Zinc Selenide components

Below components are commonly used in the field of laser, medicine, night vision or astronomy.

We can propose below kinds of optical components :

-

- ZnSe windows

- ZnSe lenses

- ZnSe aspheres

- ZnSe prisms

Zinc Selenide optical components for CO2 lasers

Zinc selenide exhibits excellent transmission at the CO2 laser emission wavelength of 10.6µm. Its crystal structure provides high resistance to thermal shock, and its relatively low hardness—approximately two-thirds that of zinc sulfide—facilitates processing. These properties make zinc selenide the optimal substrate for high-power CO2 laser optics.

Nonetheless, in order to protect the parts from scratchs and improve its transmission it is strongly recommended to apply hardening protective coating and anti-reflection layer on the optical components.