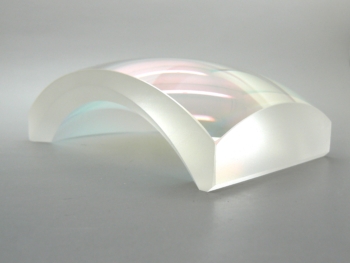

Our aspheric lens manufacturing solutions

In comparison with spherical lenses, aspheres strongly reduce spherical aberration in your optical system. Replacing assemblies of different spherical lenses by only one aspheric lens enables your optical system to be lighter, taking less space, being cheaper and remove the constraint of optical adjustment. With aspheric lens you optimize your system optical quality.

Manufacturing of aspheric lenses

Our production capabilities

Achievable specification on aspherical lenses

Achievable quality of the aspheres depends on their dimensions, material and complexity. You’ll find below for your information some typical specifications we can offer :

| SIZE | from mm up to Diam 350mm | |

|---|---|---|

| TRANSMISSION | high transmission from UV to far infrared | |

| SCRATCH & DIG | 10-5 (only on certain references) | |

| SURFACE IRREGULARITY | λ/10 | |

| DIMENSIONAL TOLERANCES | up to +/- 0,01mm | |

| CLEAR APERTURE | minimum 90% | |

| CENTERING | better than 3 arcmin | |

| COATINGS | Custom AR coatings available on request |

Available materials for aspheres

SINOPTIX offers most of optical glass present on the market. Altough it should be noted that molding of aspheric lenses is limited to glass with fusion temperature lower than 500°C. Don’t hesitate to contact us for validation of your material request.

Below are exemples of materials used by SINOPTIX for our aspheres :

| AVAILABLE OPTICAL GLASS | B270/ H-K51/ N-FK5/ N-LAF21/ N-LAF2/ H-ZK6/ H-ZK3/ S-BSM4/ H-K9L/ N-BK7/ D-ZLAF52LA/ D-LAF50/ H-ZLAF53A/H-ZF3/ H-LAF21/BD-2/H-LAK54 |

|---|---|

| IR & UV ASPHERES | CaF2/ ZnSe/ ZnS/ Germanium / Silicon/ BaF2 |

| FUSED SILICA | Corning 7980 / JGS1/ JGS2 |

| Sapphire aspheres | Al2O3 – synthetic sapphire |

| PLASTIC INJECTION | PMMA / PC |

Aspheres surface treatment

Custom AR (anti-reflect) surface treatment is available on all the aspheric lenses we are supplying. Please note that if the lenses are used with a laser, coating will be the bottle neck for the damage threshold

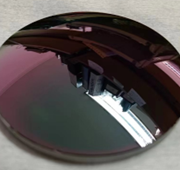

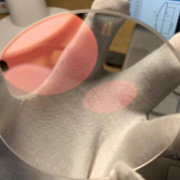

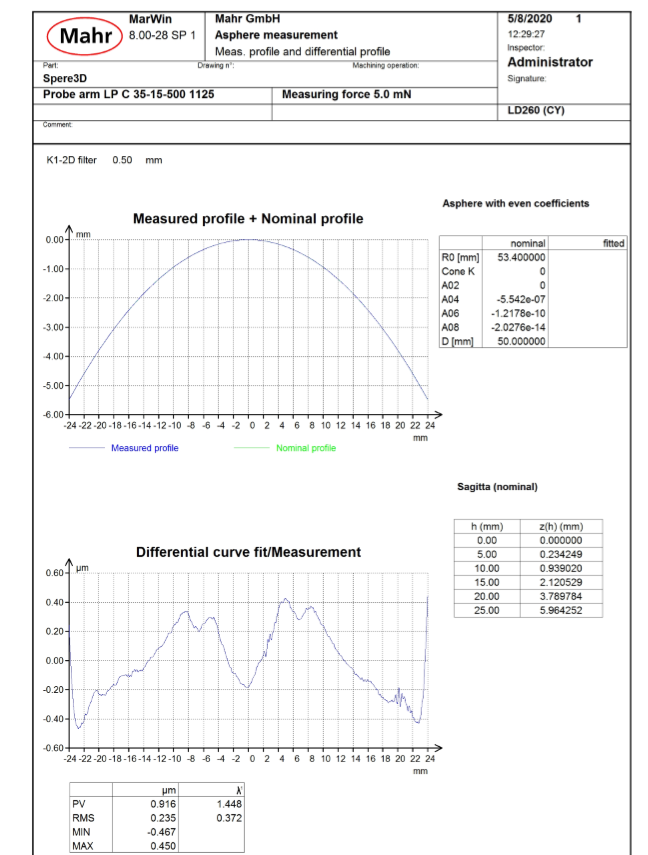

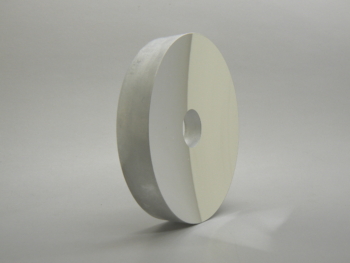

You’ll find below some examples of aspheres manufacturing capabilities, as supplied by SINOPTIX to its customers.

Aspheric lens details

Aspheric lenses or aspheres shape are defined by a conical equation as describe below

Asphere

mathematical definition of aspherical shape

Z stands for the surface (SAG) of the lens

R is the Radius of curvature

K: Conic constant

Ax: Aspheric coefficient of xth order (can be null)

Aspheric shape is more difficult to manufacture than spherical ones, that is why molded asphere parts are preferred to CNC machined ones for series order. Aspheres diamond turning is mainly used for small quantities orders, due to its long processing time and high cost.

Aspheric is an alternative to a complex system of several spherical lens, providing simpler and smaller systems.

How much will cost my aspheric lens ?

As each project is unique, don’t hesitate to contact us for a quote, please be sure to provide below information:

- Technical drawing following ISO10110 norm, including surface aspect specifications

- Conic constant and aspheric coefficients as defined above or an array of coordinates of aspherical surface of the lens.

- Material

- Wavelength range for an eventual AR treatment

- Expected quantities

After receiving your request, we will come back to you shortly by email with a quote of your aspheres delivered to your place.

how to produce aspheric lens ?

Aspheric lenses can be manufactured per different processes:

- Precision Molded (preform heated and pressed between to matrix)

- Diamond turning

- CNC grinding and polishing

- MRF (magneto-rheological finishing)