Optical mirrors

Optical mirrors are defined as objects that reflect light beams at a special wavelength range following optical specifications. SINOPTIX offers solutions for any need you have on custom optical mirror.

Range of our optical mirrors offer

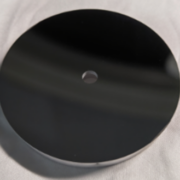

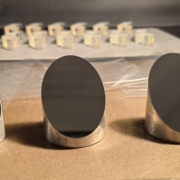

We offer a wide selection of mirror types, including spherical mirrors, parabolic mirrors, elliptical mirrors, flat mirrors, and more, in various shapes, sizes, coatings and substrates to meet your specific requirements.

Of the wide option of coatings we offer, here is the most commons :

- Aluminum & protected aluminum, most common coating up to 98% of reflection from the near UV to IR.

- Silver coating, offer a higher reflectivity in the visible range, up to 99.9%. however, the silver coating is less stable than aluminium as it is more sensitive to external environment.

- Gold coating, often the preferred choice for IR mirrors, as it offers a better heat dissipation (especially interesting in the thermal infrared range) and is much more stable that aluminium and silver to external elements.

- Dielectric coating, refers to thin film deposition of material with specific optical characteristics, are particularly used for custom coating on specific wavelength. Have also a higher LIDT (resistance to power lasers) than metal coating.

Our team of experts is always available to assist you in choosing the best optical mirrors for your application, and we are committed to providing excellent customer service and support throughout the ordering and delivery process.

SINOPTIX optical mirrors references :

Ensure a good reflection

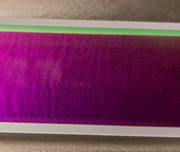

In order to ensure a good quality of your components, our experienced team assures that coating quality is matching requirement by measuring reflection of the coated mirrors. I is also important to control the quality of the substrate both in shape and aspect which is done by dimension measurements and interferometre.

To better understand optical mirrors, please refer to our free complete guide online.

Usage & applications of optical mirrors

There is mainly 3 different reasons why mirrors may be used :

- Deviation of the path of light. This can range from periscope, complex optical system to laser scanning mirrors.

- Lowering the optical signal loss, optical component like lenses are mainly used in transmission, going through the component material create absorption loss that can be avoided with mirrors. This is particularly used in astronomy (Cassegrain telescope) or high power laser applications.

- Alternative to optical component when they are not usable, for example almost no material is transparent to extreme UV light, optical mirrors are the only usable option for EUV applications.

How to buy optical mirrors ?

In order to get the requested quality and the best quotation it is important to provide detailed specifications, provide technical drawing and confirm needed quantities.

Specifications to provide (we can help if unclear) :

- Wavelength range of working

- Surface quality

- Shape definition (equation if complex conic shape)

- AOI (angle of incidence)

- Type of coating (we can help)

- Requested substrat material (we can help)

With all these information, SINOPTIX will be able to quickly provide you with a very competitive quote.

sinoptix.eu

sinoptix.eu