ZnS / Zinc Sulfide IR optical component : a complete guide

Often mistaken with ZnSe (Zinc Selenium), Zinc sulfide (ZnS) is also a material very popular for infrared applications. As it has a broader transmission in the visible spectrum it is almost colorless for thin components of multispectral grade, while it shows a slight yellowish aspect for the FLIR grade.

ZnS optical disc

Why is ZnS / Zinc Sulfide a good optical material ?

Zinc Sulfide material used in Optics has a cubic crystal structure. It can be manufactured in two grade : FLIR ZnS and multispectral ZnS.

FLIR ZnS grade

“FLIR” refers to Forward Looking Infrared as material will be optimized for the 8-12µm thermal IR spectrum. The FLIR grade is manufactured by CVD process (Chemical Vapor Deposition) and will be in the form of mono-crystalline blocs of material. As mentioned above material will have a yellowish color.

Multi-spectral ZnS grade

Multi-spectral ZnS grade is also manufactured by CVD, but will necessitate a post processing to enhance its optical properties homogeneity accros the transmission spectrum from FLIR down to visible. This post processing is called Hot Isostatic Pressing (HIP). By applying high pressure and high temperature the crystal lattice is “healed” of most defects.

ZnS / Zinc Sulfide : properties

Properties chart of Zinc Sulfide :

| Property | Values |

|---|---|

| Material name | Zinc Sulfide |

| Chemical formula / Chemical element | ZnS |

| Material structure | Mono or polycristalline cubic structure |

| Color | Clear to Yellowish |

| Index of Refraction | 2.2 in the visible (2.89 @ FLIR) |

| Transmission range | 370nm to 14µm |

| Density | 4.09 g/cm3 |

| Hardness | 210-240 kg/mm2 |

| Young’s modulus | 74.5 GPa |

| Thermal expansion | 6.8*10-6 °K-1 |

| Thermal conductivity | 16.7 W/(m*°K) |

| Melting point | 1293 °K (1020°C) |

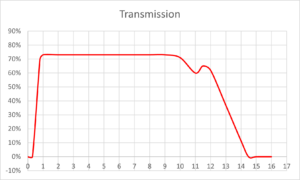

Transmission curve of Zinc Selenide

ZnS transmission curve

What type of optical component can be made in ZnS ?

While Zinc Sulfide is harsher than ZnSe material it is still easy to process and therefore offers a broad possibilities of components :

-

- ZnS windows : used for Thermal / FLIR application sensors/cameras or as a multispectral window.

- ZnS lenses : spherical lenses and aspherical ZnS lenses are often used in IR vision systems.

- ZnS domes : used mostly for rocket heads.

General specifications for ZnS windows and lenses

| Properties | Values |

|---|---|

| Available dimensions | Diam 3 to D200mm |

| Dimensional tolerances | +/-0.05mm |

| Surface quality | S&D : up to 40/20 |

| IRR | up to 1/20 lambda |

| Coatings | Multi-spectral or AR 8-14µm |

Above value are generic specifications for fabrication, specific better value may be available and need to be reviewed case by case.

ZnS or ZnSe which one to choose ?

While having very similar names both material have specifics.

- ZnSe has a lower absorption @10.6µm which make it the preferred material for CO2 lasers.

- ZnS have a wider transmission in the visible but shorter in the far infrared, selection should be made according to spectrum of interest.

- ZnS is stronger and more resistant than ZnSe, and therefore to be recommended in case mechanical strength is important.

Where to buy Zinc Sulfide IR optical component ?

ZnS substrate are very rare naturally and therefore most of the raw material is crystal grown in laboratories.

IR precision optics suppliers provide all kind of Zinc Sulfide optical components and can also offer optical coatings for enhanced characteristics.

Don’t hesitate to contact SINOPTIX for more details or request for quotation.