Optical lens: a complete guide

When we speak of optics, optical lens is the first optical component that comes to mind, and indeed optical lenses are now everywhere in our everyday life. We will see the different types, their manufacturing process and their different applications.

Definition of an optical lens

An optical lens is a passive optical component that is transparent to wavelength in the optical field (from deep UV to far IR) and that will alter the path of light either in converging or diffracting the light.

Most common optical lenses are made of optical glass (from main manufacturer like : Schott, Corning, Ohara or CDGM) but can also be made of metal (Germanium) or other materials (ceramics, Silicon, Zinc selenide, sapphire, polymers etc.).

The quality of an optical lens is defined by its ability to reproduce a nominal shape and the quality of its polishing.

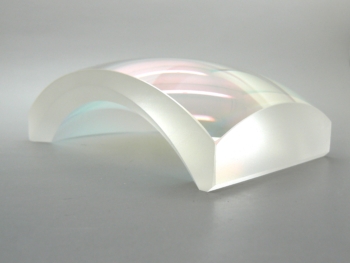

Illustration of optical lenses

Production process of an optical lens

There are three main process for producing an optical lens:

-

Lens Molding:

The material is cut in preform of specific dimension, heated and then pressed in hot tooling. After unmolding, finishing is done, like grinding of the edges or final polishing can be requested according to the quality requirements and the quality of the tooling.

-

Lens grinding and polishing:

The process also referred as cold machining consist of removing material with mechanical friction of grinding or polishing pads including hard grains. The process usually long (some hours) can be semi automated or partially automated. The polishing pads are changed several times along the process with smaller and smaller grain in order to reach the required quality. The higher the polishing quality request, the higher the time a lens need to be polished.

-

Diamond turning:

Diamond turning is usually used for complexe shapes and don’t necessitate further polishing. The equipment is similar to a CNC machining center where lenses are made one by one.

-

Pro & cons of lenses different production methods

Lens production method ProS CONS Lens molding Cheap unit cost for large quantities Not ok for small quantities, limitation in size and material (low fusion point) Lens grinding and polishing Several lens can be worked together, relatively cheap production equipment Long processing time, not fit for high quantities orders Diamond turning Very good optical quality Expensive (modern equipment, parts manufactures one by one). -

Coatings and finishing of lenses

In order to enhance the optical properties of a lens, optical coatings are often applied on the lens. Optical coatings consist of thin layer(s) of metal or chemical elements that can reduce reflection of light on a certain wavelength range these coatings are called AR (Antireflect) coatings.

Types of optical lenses

There are many different categories of optical lenses that can be described in below index:

| Type of lens | SHAPE DeTAIL | USAGE |

|---|---|---|

| PCX lens | Plano-Convex lens | focusing light on one point or enlarging an image |

| PCV lens | Plano-Concave lens | focusing light on one point or enlarging an image |

| Biconcave or Biconvex lens | Concave-Concave or Convex-Convex | focusing light on one point or enlarging an image |

| Meniscus lens | Thin concave-convex lens | focusing light on one point or enlarging an image |

| Spherical lens | Shape defined by a center and a constant curvature radius | Easy to design and to manufacture |

| Aspherical lens / asphere | Shape defined by a center and a changing curvature radius (conical equation) | Better imaging (less spherical aberrations) |

| Cylindrical lens | Shape defined by a center axis and a constant curvature radius along this axis | focusing light on one dimension (line) |

| Toroid lens | Shape define with two different orthogonal radius of curvature | used for cornea simulation |

| Achromatic lens | Doublet or Triplets lens : two or three complementary lenses cemented together | compensate the color aberrations (difference of focal points according to wavelength) |

Design of an optical lens

Designing of optical lenses can be done with specific software, Zemax being the most famous of them. It usually require optical designer with sound understanding of optical materials, optical shapes and optics manufacturing constraints.

As optical lenses specifications are complex, we recommend to design them according to the ISO10110 norm, in order to get quicker and more accurate quotes.

Applications

Optical lenses are used in many areas:

- Astronomy (telescopes)

- Electronic appliances (mobile phones)

- Security (CCTV cameras)

- Defense (targeting systems)

- Vision (production monitoring or quality checking)

- Transport (LIDAR systems)

- Other photonics applications

Picture of a meniscus lens with AR coating

Optical lens pricing

The cost of an optical lens depends on many factors and therefore need detailed analysis in order to get it right :

- Raw material

- Quantities (optical lens manufacturing is time consuming, but some process can be done in parallel, which means that higher quantities can lead to very important price decrease)

- Shape

- Optical specifications, the higher the optical specifications the higher the price, the price increase can be exponential for just a small amelioration of an optical property.

- Coating

- Size : oversize optics and micro-optics both need specific attention and tooling and therefore are much more costly that standard dimension optics (in the centimetres area).