Optical prism : a complete guide

Most of us remember the famous rock band Pink Floyd’s “Dark side of the moon” album cover showing a light beam been diffracted in a “rainbow” through a triangular prism. That is a very good summary of how light beam travel through a prism, below you’ll find a complete guide to look further in optical prisms.

What is a optical prism ?

Definition

An optical prism is a bloc of optical material cut in geometrical shape for the specific purpose of modifying the incident light beam by affecting it’s direction, rotational angle or diffraction.

In optical systems they are used to turn a signal or separate the signal according to it’s wavelengths.

Specifications

Many different optical materials can be used to manufacture a prism, depending of the type of prisms and the wavelength range they will be used in. Optical prisms can be provided with below materials :

- Optical glass : B270, H-K9L / NBK7, F2, N-SF11

- Fused silica

- IR material : CaF2, BaF2, MgF2, Silicon, Ge

- Sapphire

- Many other references

Below table shows the typical specifications / tolerances for optical prism manufacturing :

| Specification | Detail |

|---|---|

| Dimensional range | 0.3mm to 300mm |

| Dimensional tolerances | +/- 0.1mm (normal) or +/-0.05mm |

| Surface flatness | up to Lambda /10 |

| Surface quality | S&D 40/20 |

| Angle tolerance | up to +/- 1 arcmin |

Prisms can be coated, AR to reduce signal reflection on the surface or Reflective coatings to enhance the signal reflection at specific wavelengths.

Different types of optical prisms

| Type of prism | Description | Usage | Image |

|---|---|---|---|

| Right angle prism | Prism with a right angle triangular cut shape with both sides opposite to the hypotenuse of equal dimension. | They are used to deviate a light path to 90° or 180° by TIR (Total Internal Reflection) |  |

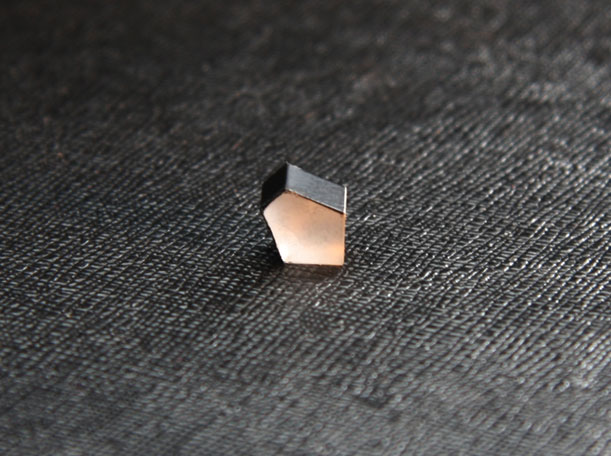

| Penta prism | Prism with a pentagone cut shape, with specific angles. | Penta prisms are used to redirect a signal by 90° without inverting nor reversing the image. |  |

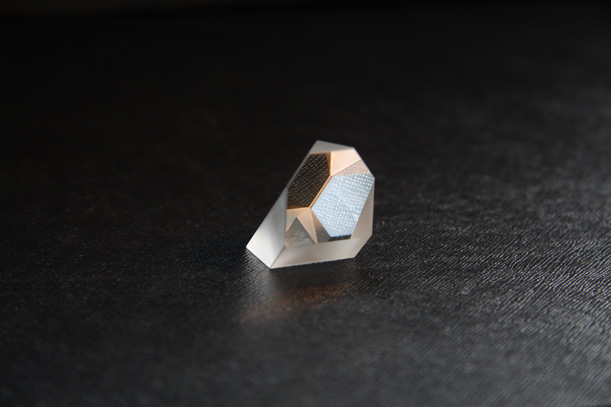

| Retroreflector | Round base prism with three face pyramidal sphape. | Return the light at 180° even without alignment of the incident light and the retroreflector. Used in topograply and other applications. |  |

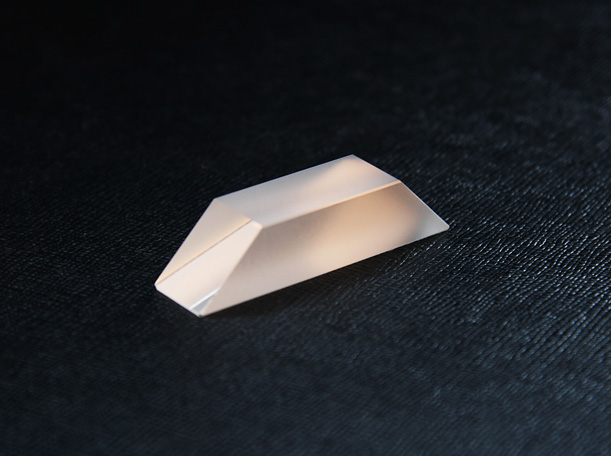

| Dove prism | Parallelepiped which correspond at a truncated right angle prism. | Rotate the image with no deviation of the beam. The rotation angle is equal to twice the prism optical axis angle compare to the incident beam. |  |

| Roof prism | Roof shaped prism. | Used to deviate the signal at 90° while inverting it. |  |

| Equilateral prism | Prism made of high diffractive Abbe number glass in a shape of an equilateral triangle. | Used to disperse the light with different angles for each wavelength. (think of the Pink Floyd album cover). |  |

| Pellin Broca prism | Quadrilateral prism with angles of 90°, 75°, 135° and 60°. | Deviate the light by 90°, used in spectroscopy and for harmonic separations. |  |

| Wedge prism | Prism made of a plan surface and and other tilt surface. | Used to deviate light signal (mostly for laser beams) |  |

| Micro prism | Prism with dimensions between 0,3 and 3mm of side. | Used in optical fiber sysems and endoscopy. |  |

| Glued prism | Assembly of custom prism made by gluing / cementing, can include air space in between parts. | Custom made to fit customer applications. |  |

Prism manufacturing

The process of manufacturing a prism will usually follow below steps:

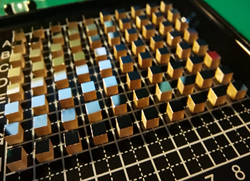

- Raw material bloc cutting.

Cutting glass prism into shape.

- Fine grinding and polishing of the optical surfaces.

Cluster of prisms glued together to prepare polishing

- Final cutting to shape

- Cleaning in ultrasound bath.

Underwater ultrasound cleaning of optical prisms.

- Eventual surface treatment application.

Optical coating device.

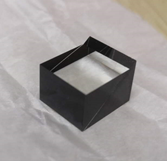

The prisms can be further assembled either cemented with other optical elements or assembled in opto-mechanical parts.

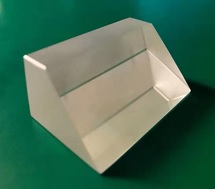

Two prisms cemented together with air gap in between and black varnished sides.

Where to buy optical prism ?

If you are looking for prisms to be used in optical application, you should look for precision optics suppliers, with experience in the optical material you are looking for.

Please note that as you can notice above in the description of the manufacturing process, optical prisms can be manufactured in parallel, for almost each step, therefore order quantities are a key point in manufacturing cost valuation.

Prepare all the below information :

- Material

- Technical drawing

- Coating request

- Expecting quantities

And then send your request to your favorite precision optics supplier. By click on the below you can contact SINOPTIX directly for your request.