TPX optics : buying guide

Due to it’s interesting optical properties, light weight and relatively good resistance TPX is experiencing more and more interest from photonics industry. Let’s learn more about this material and it’s applications.

What is TPX ?

Definition

TPX stand for Transparent Polymer X. It is a Mitsui registered Trade mark of Polymethylpentene (or PMP). It can be used as raw material for polymer machining, plastic injection, extrusion or even in the form of thin film.

TPX shows good transparency for a very extensive range from the UV to the THz area. It shows also very good electric insulation properties, good resistance to moisture and heat.

Moreover Polymethylpentene is the lightest (see below details) of the polymers, and shows a stable a relatively low refractive index (low dispersion).

Specifications

In below table you’ll find most common characteristics of TPX

| Characteristics | Values | Remarks |

|---|---|---|

| Density | 833 kg/cm3 | lightest of all polymers, less than half lighter than PTFE |

| Melting point | 232°C | |

| Vicat softening point | 168°C | |

| Heat distortion T° | 127°C | |

| Water absorption | less than 0.01 percent | ASTM-D570 |

| Volume resistivity | >10^16 ohm.cm | |

| Yield stress | 30 Mpa | ASTM-D570 |

| Rockwell Hardness | 83 | HRR scale |

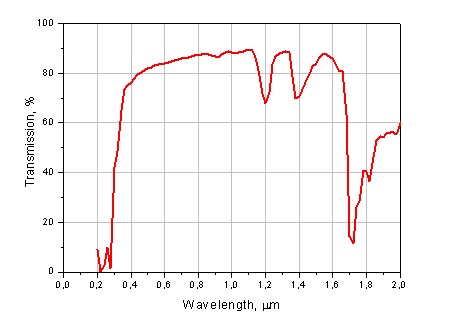

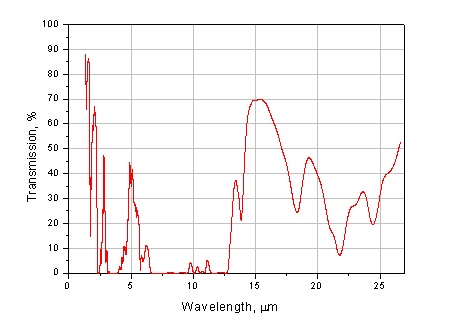

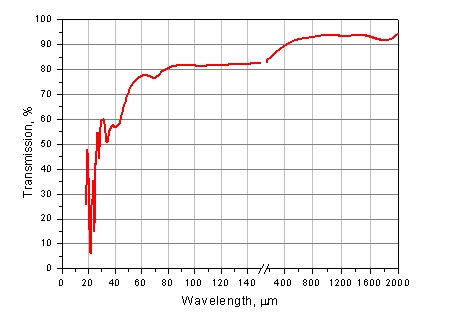

| Transmitance | 94%* | *in the THZ area. See below curves for other wavelengths. Best THz transmission. |

| Refractive index | 1.463 | in the visible range, varies between 1.46 & 1.466 in the THz range |

It is interesting to note that the material has been validated by FDA administration for food processing usage.

Moreover, as it is halogen free it is considered as an environment friendly material.

Which optical components are available in TPX ?

Polymethylpentene can be formed and polish into several kind of optical components :

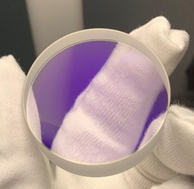

- TPX windows due to material’s low refractive index, windows can be used with high AOI

- TPX lenses

- TPX cylindrical lenses

- TPX film

- Other (prisms, light guides, Brewster windows, etc.)

! Since TPX is mainly used in THZ application where surface quality aspect is not very important, it is important to require high quality polishing if the component is to be used in the visible / UV range too.

Advantages to other THz optics

Other materials that my be used for THz applications, including HRFZ-Silicon, PTFE (Teflon), Z-cut quartz, COP, COC and Sapphire.

The advantage of TPX is better transmission in the THz vision, wider range of transmission (from UV to THz), lighter material.

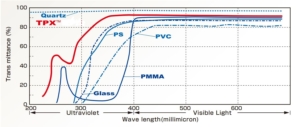

Comparison chart of UV transmission of different polymers and glass.

Outdoor usage of TPX optics is not recommended as it may lead to color change and quality deterioration

Why using TPX optics in cryogenic systems ?

Compare to other THz optics like HDPE and HR-Si, TPX shows a good thermal stability, meaning that working at cryogenic temperature will almost not affect its mechanical properties. It’s thermal resistance will avoid condensation on it’s surface hence keeping a good optical ability when temperature change.

The low refractive index of TPX is also a plus as less optical deformation will occur. Finally, the material have a continuous high transmission spectrum from infrared to THz.

Different usage of TPX windows

As the optical transmission range is very extended from UV to THz, many applications can be found, here are the most commons :

- TPX windows are often used in vacuum chambers as they can be used down to 10-9 mm.Hg.

- Cryogenic products

- Food processing

- Medical apparatus

- THz emitter and cameras

- Research

How much do TPX optics costs?

Due to the complexity of it’s manufacturing and relatively limited production actors, TPX material is rather more expensive than other polymers.

Fortunately the material is rather easily processed and polished which helps keeping TPX optical components costs competitive, especially against HRFZ-Si and sapphire.

As each project, specifications and quantities are different it is better to contact THz optical components manufacturers for getting a price for a specific component.