Aspherical lens : a complete guide

Improvement of production technology has brought a democratization of the use of complex aspherical lenses. What are their benefits, how to manufacture them, see our guide below for answers.

What is an aspherical lens ?

An aspherical lens can be defined as a non spherical lens with at least a one optical face that can be defined following below conical equation.

mathematical definition of aspherical shape

Z stands for the surface (SAG) of the lens

R is the Radius of curvature

K: Conic constant

Ax: Aspheric coefficient of xth order (can be null)

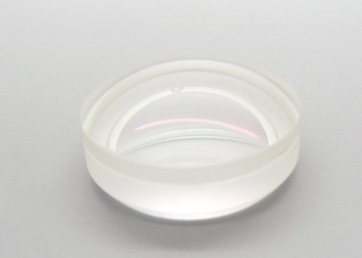

Artistic view of an asphere

Advantages of aspherical lens.

Spherical lenses are easy to manufacture, but it has been identified by early opticians that using these lenses comes with aberrations on the image, called spherical aberrations. To compensate these aberration one can use doublets or complex systems of lens but this is costly and will take more space and weight.

The other solution to remove the spherical aberration is to design the shape of the lens to avoid it, these complex shapes are defined by conical equation and are defined as aspherical shapes. Manufacturing of aspheres is more complex, but with recent (last 20 years) digitalisation of the production and testing equipment it becomes easier and cheaper.

How are aspherical lens manufactured ?

Aspheric lenses can be manufactured per different processes:

| Production method | Description | Details |

|---|---|---|

| Precision molding | raw material blank is first pressed between to metal matrix at high temperature (400 to 650°C) for several minutes , then a controlled cooling is done and the releasing of the final part is done without further polishing |

|

| Diamond turning | Using a very small diamond head to work the surface of the lens. |

|

| CNC (Computer Numerically Control) | Grinding (with ring or disc tools) and polishing (with small polishing pads). |

|

| MRF (magneto-rheological finishing) | Special polishing method used after CNC grinding. Polishing medium viscosity is controlled with a magnetic field enabling a custom polishing. | Better precision than normal polishing. |

CNC grinding equipment for aspherical lens

How to measure an asphere ?

There are different methods to measure the surface accuracy of an asphere which can be divided by contact measurements with probes and non contact measurements using interferometers and accessories.

| Contact measurement solutions | ADvantages | Disavantages |

|---|---|---|

| CMM (Tri-dimension measurement). |

|

|

| Profilometre |

|

|

CMM measurement of the surface of a lens

| Non contact measurement solutions | ADVANTAGES | DISAVANTAgeS |

|---|---|---|

| Subaperture Stiching Interferometry |

|

|

| CGH (Computer Generated Hologram) |

|

|

| Spherical Null lens |

|

|

| Verifire (Zygo) |

|

|

Zygo Verifire setup for asphere measurement

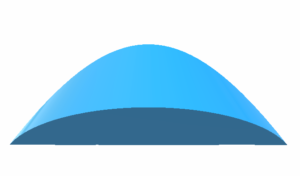

What is the difference between a spherical lens and a aspherical lens ?

The difference between both lenses comes from their shape, while a spherical lens shape can be defined from a virtual center and a fix radius of curvature, an aspherical lens shape is defined from a virtual center point point but with different values of radius of curvature according to their relative angle.

For a simple image comparison, a spherical lens can be seen as a cut of a sphere whereas an aspherical lens can be defined by more complex shapes, for example conic or elliptic.