Glass work, our techincal glass manufacturing solutions

SINOPTIX is also a provider of glass parts that are used in industrial applications not related to optics. These glass parts are manufactured according to different process : tube extrusion, glass blowing, glass machining or glass molding. We provide custom glass parts matching high tolerances with nice cosmetic aspect. Glass is not an easy material to work with, but it as some interesting characteriscs, beeing transparent, hard, inert and resistant to chemicals and high temperature.

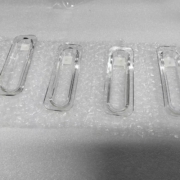

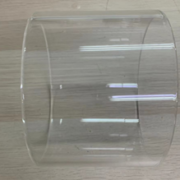

Glass tube

Glass tubes are blown and extruded to dimensions, we can provide custom dimensions for your glass tubing for small quantities to big series.

Glass tubes are mainly of fourtypes:

- Borosilicate tubes (can be colored borosilicate tubes)

- Quartz tubes (transparent or milk quartz tubes)

- Soda-lime glass tubes

- Sapphire tubes

On top of producing glass tubes to your dimensions we may custom them with grinding, cutting, fire polishing and chanfreining.

Moreover the range of dimensions is very flexible, from thin milimeter tubes up to 1m diameter wide tubes.

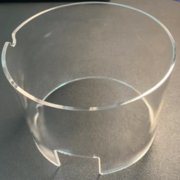

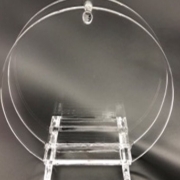

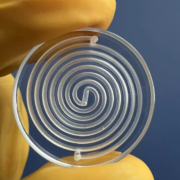

Glass machining

There are solutions for providing glass parts with cuts, drills, stages and other machining. Custom made glass parts can be made from 1 prototype part to several thousands quantities.

As it is much brittle than metal or plastic, glass machining comes with constraints, not all shapes are possible, chanfreining of borders are recommended to avoid cracks. Let us advise you on your project faisability.

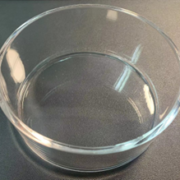

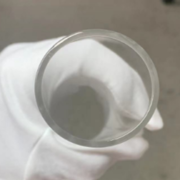

Container glass | glass blowing

We supply container glass, crucibles, bottles, test tubes at your specifications. They can be made from glass blowing, glass molding or glass machining, don’t hesitate to contact us for the feasability and quotation of your project.

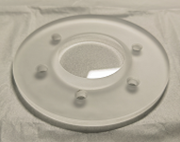

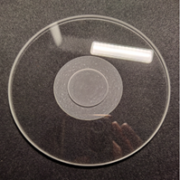

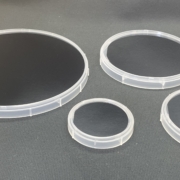

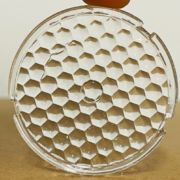

Pressed glass | Molded glass

Molded glass parts are available for big quantities projects, usual precision of pressed part is low, but can be improved by further processing.

Before being pressed or molded the glass should be cutted to a preshape and heated to become viscous and malleable. Conroling of the size of the precut and the temperature stability along the process is key for the reproductibility of the parts, goods equipements are therefore important so are the skills of the producing staffs.

Technical Glass process

Sinoptix introduces various processes for your technical glass projects.

Glass is a relatively difficult material to work due to the risk of breakage and its hardness. There are two main categories of glass working:

– Hot work (allow complex shapes)

–Cold work. (Easier to perform, but needs more time so the cost may increase).

1/ HOT WORK

Glass blowing :

Artisanally the blowing of the glass is always carried out using a cane, on which the blower will come deposit a mass of molten glass

Artisanally the blowing of the glass is always carried out using a cane, on which the blower will come deposit a mass of molten glass

(Gob). This mass is then worked during cooling to give the desired shape to the part. However, this technique is used very little for the industry whose requirements of form and tolerances are more stringent, and often reserved for artists.

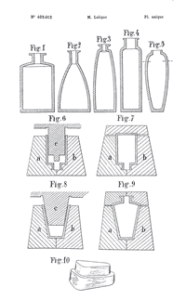

The industry uses other processes such as blow molding. This process is used in most non-flat glasses, such as food containers or any other so-called hollow glass. Several methods can then follow one another to produce a part.

The glass can be pressed : The molten glass falls into a mold and then a punch goes down to give shape to the piece. This process is limited to simple shapes. Then it is possible to add a blowing step to reach the desired final shape. This is pressing-blowing , which allows the production of more complex shapes when a product with a larger volume is sought.

The glass can be pressed : The molten glass falls into a mold and then a punch goes down to give shape to the piece. This process is limited to simple shapes. Then it is possible to add a blowing step to reach the desired final shape. This is pressing-blowing , which allows the production of more complex shapes when a product with a larger volume is sought.

It is also possible to rotate the mold during blowing. This is press-blow-rotate . This guarantees a glass with thin and uniform walls, a process used in laboratory glassware for example.